We’ve put together a guide to help answer any questions on the expert specialty printing techniques we offer.

Digital printing uses toners that sit on the surface of the paper. Multiple colors and/or photographs are printed with one pass through the press, so there are no additional charges for additional colors.

Papers with a smooth (not textured) finish are recommended for the best results.

Digital printing can accommodate paper up to approximately 130# cover weight.

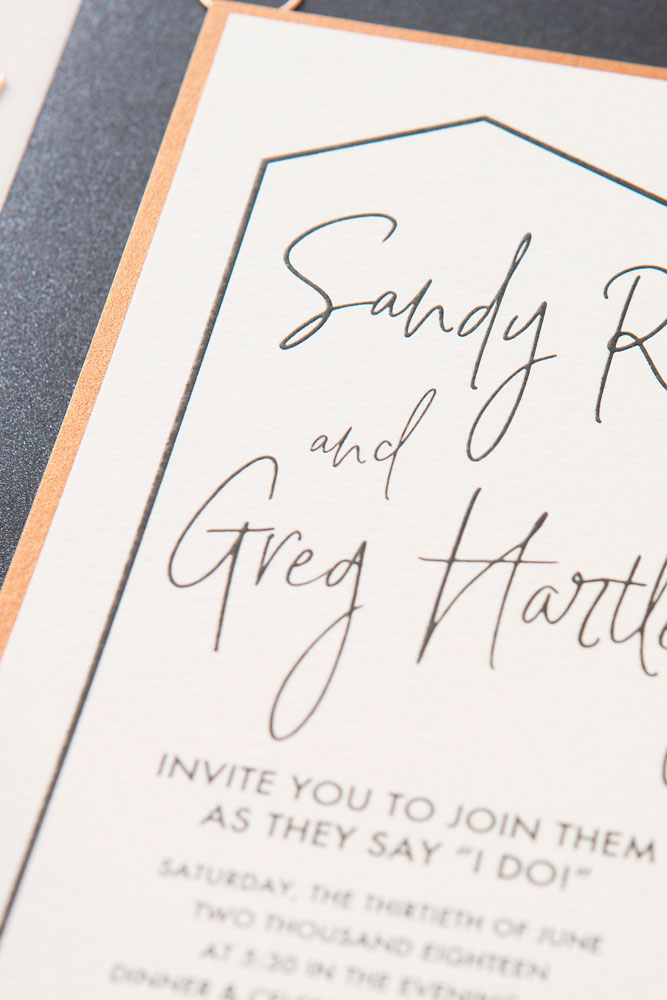

Offset printing is created using film negatives and thin, pliable metal plates. Offset printing is a high quality, beautiful printing method that results in a flat (not raised or indented) ink on the surface of the paper.

Offset printing can accommodate paper up to approximately 130# cover weight.

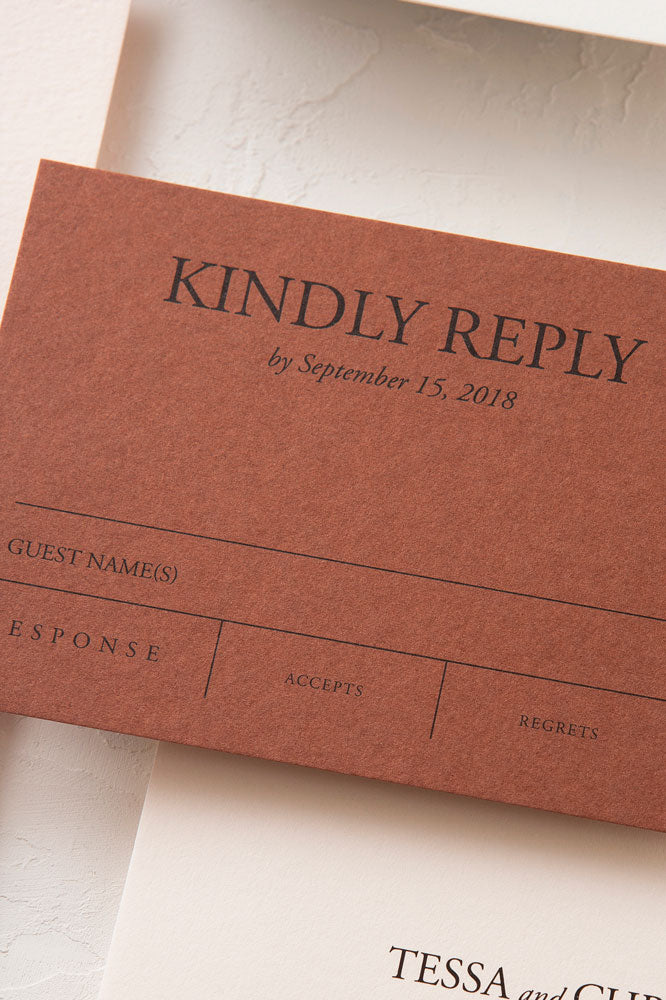

Thermography printing is created by applying a fine powder to wet, offset ink and then heating to a high temperature. The heat causes a chemical reaction that bubbles the ink slightly resulting in a raised effect.

Thermography printing can accommodate paper up to approximately 130# cover weight.

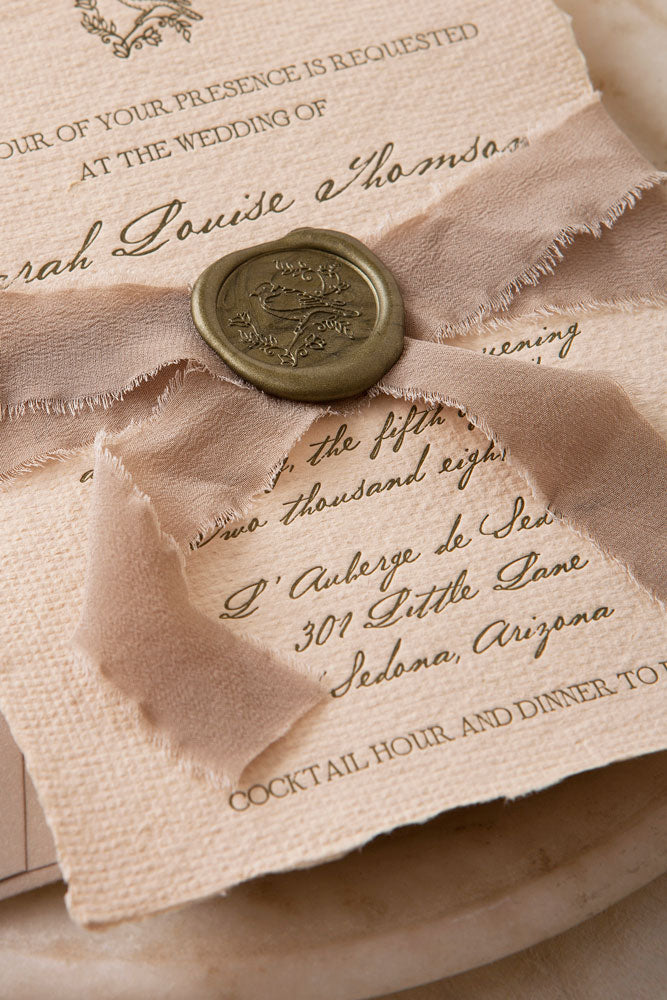

Letterpress printing is created using a dimensional die that presses ink into the surface of the paper. Soft paper selections with a high cotton content will result in a deeper, more tactile impression in the paper.

Letterpress printing can accommodate paper up to approximately 330# cover weight.

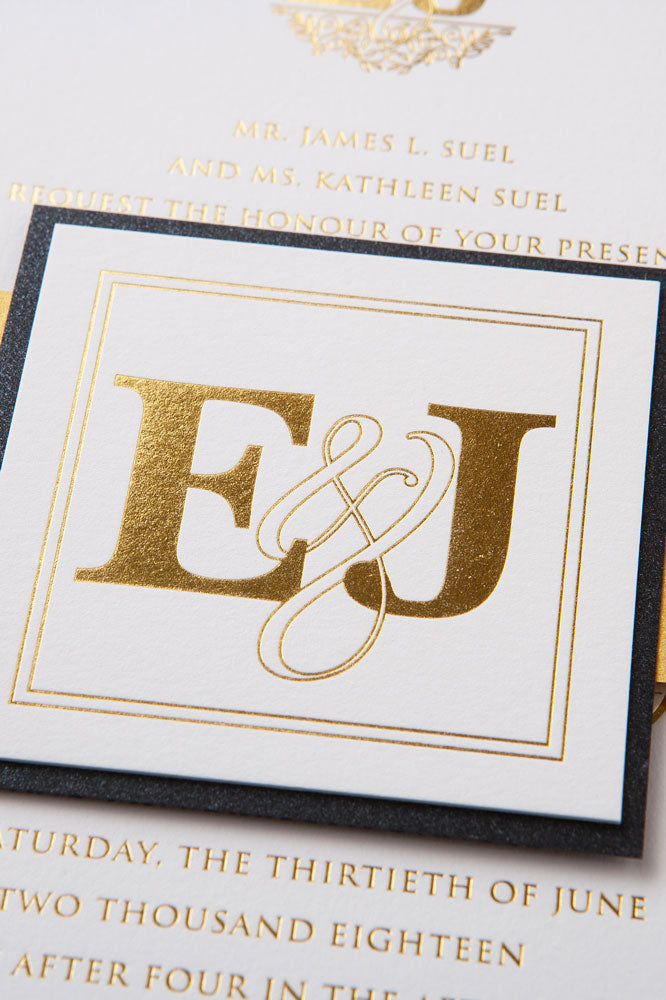

Foil Stamping, also known as hot stamping, is created using a dimensional, heated die. The heat from the die transfers the foil onto the paper. Foil is the perfect method for achieving a reflective metallic effect.

Foil Stamping can accommodate paper up to approximately 330# cover weight.

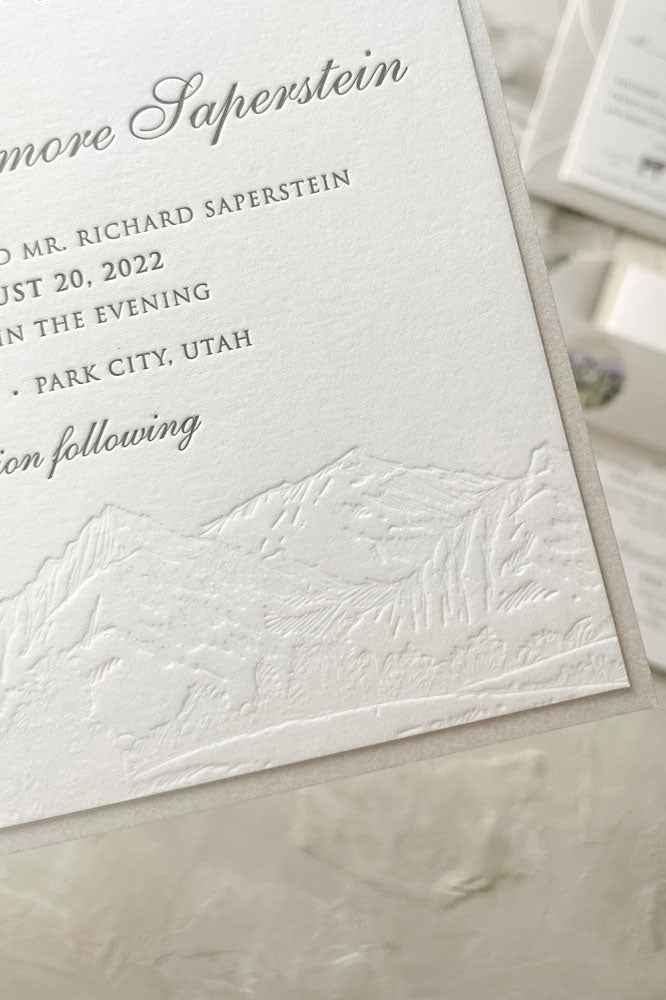

Embossing is when the design or logo is raised by pushing a metal die into the paper from underneath. The raised area can have ink or foil stamping applied but can also be left unprinted or unfoiled, also known as blind embossing.

Embossing can accommodate paper up to approximately 330# cover weight.

Debossing is the opposite of embossing. The design or logo is created by indenting the paper with the metal die onto the front of the paper. You can choose to leave the debossing as is (blind deboss) or you can fill the indentation with ink.

Debossing can accommodate paper up to approximately 330# cover weight.

Digital Gold Ink printing is achieved by the use of ink formulated with metal particles. The opaque metallic ink is more of a matte finish and is less reflective than foil. If you want a high gloss, we suggest you go with foil stamping.

Digital printing can accommodate paper up to approximately 130# cover weight.

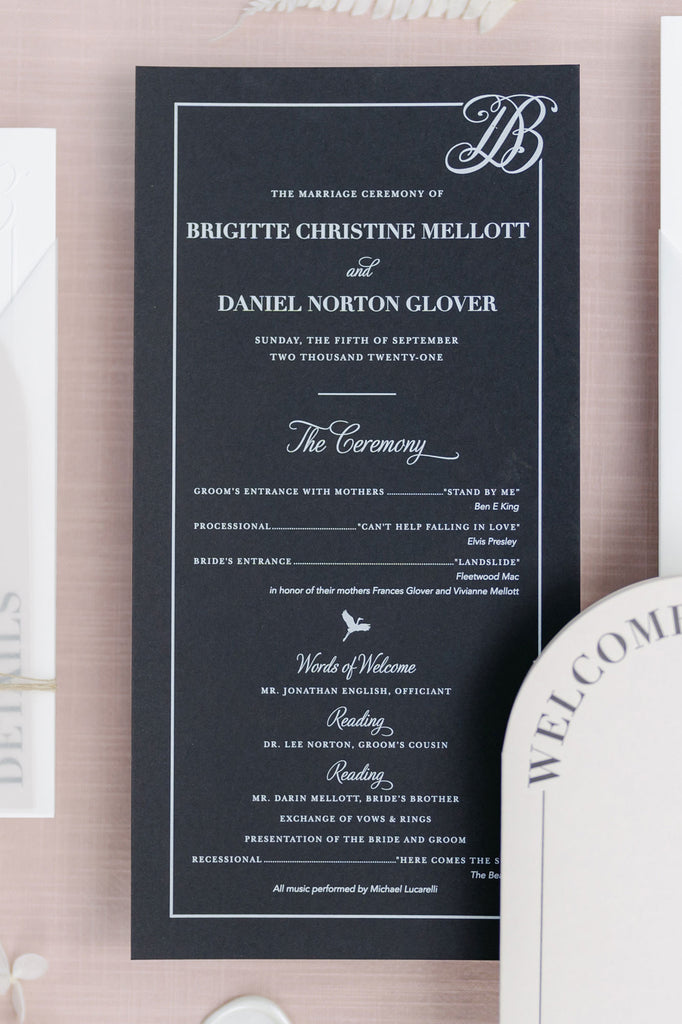

Digital White Ink printing is achieved by the use of white toner. The white ink is opaque and has more of a matte finish. We recommend using white ink printing on darker color stocks.

Digital printing can accommodate paper up to approximately 130# cover weight.